Product Videos

Case Studies

FAQ

-

How long can a PipeSak® Geotextile Pipeline Weight (GPW) sit in the sun?

PipeSak® GPW’s are manufactured using high-grade geotextile grade fabrics that have been treated for UV exposure.

When filled, PipeSak® GPW’s withstand direct sunlight for a minimum of 500+ hours (approx. 50 – 120 days, depending on conditions and time of year).

If filled PipeSak® GPW’s are expected to be exposed to the elements for extended periods, in excess of 6 months. We recommend they be covered by a tarp or silage wrap.

Empty PipeSak® GPW’s are packaged with a UV resistant cover designed to protect them from the elements for extended periods of time.

-

Will a PipeSak® Geotextile Pipeline Weight (GPW) block cathodic protection?

No, PipeSak® GPW’s will not block or impede cathodic protection systems.

PipeSak® GPW’s are manufactured using a permeable geotextile fabric rated for underground use. When filled, PipeSak® GPW’s are as permeable as the ballast they are filled with.

-

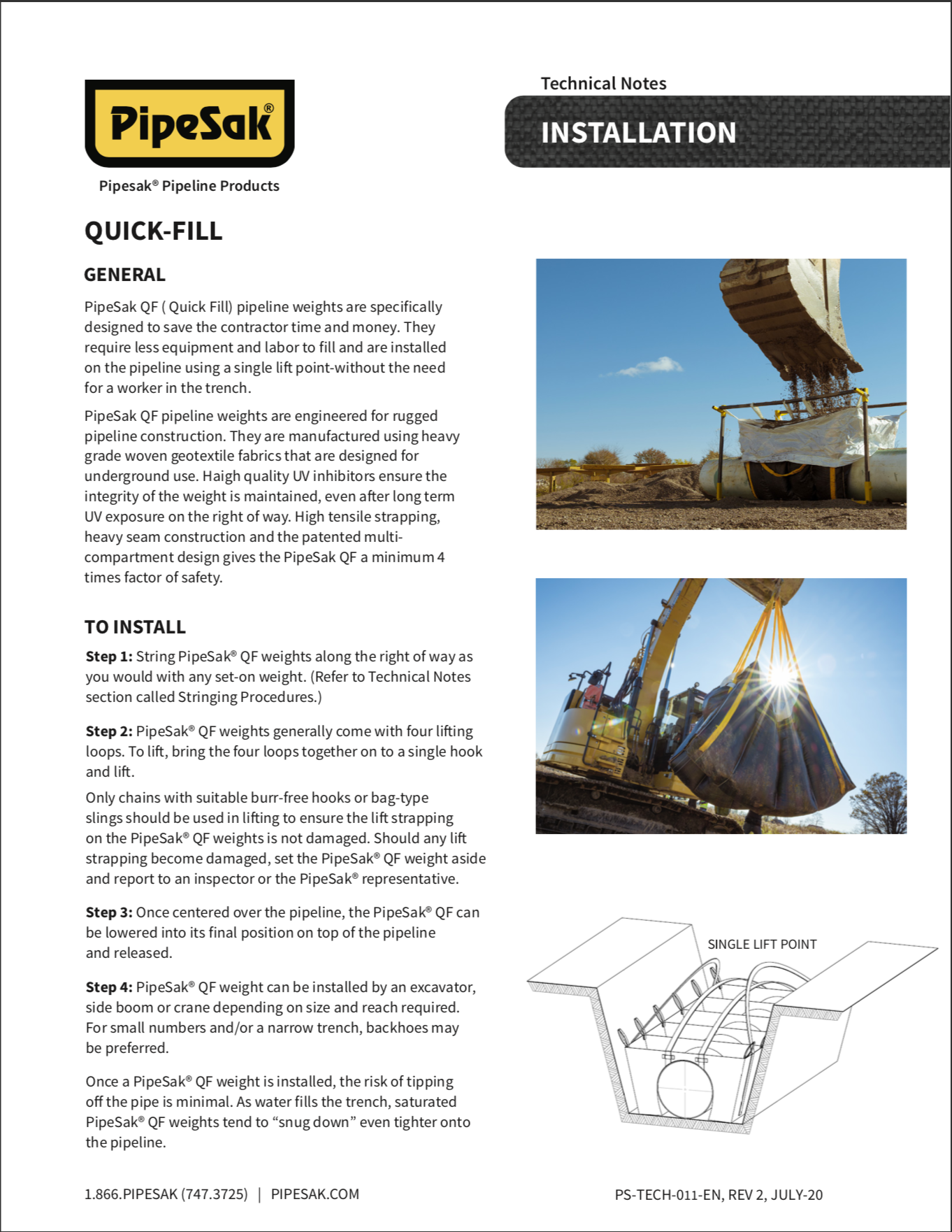

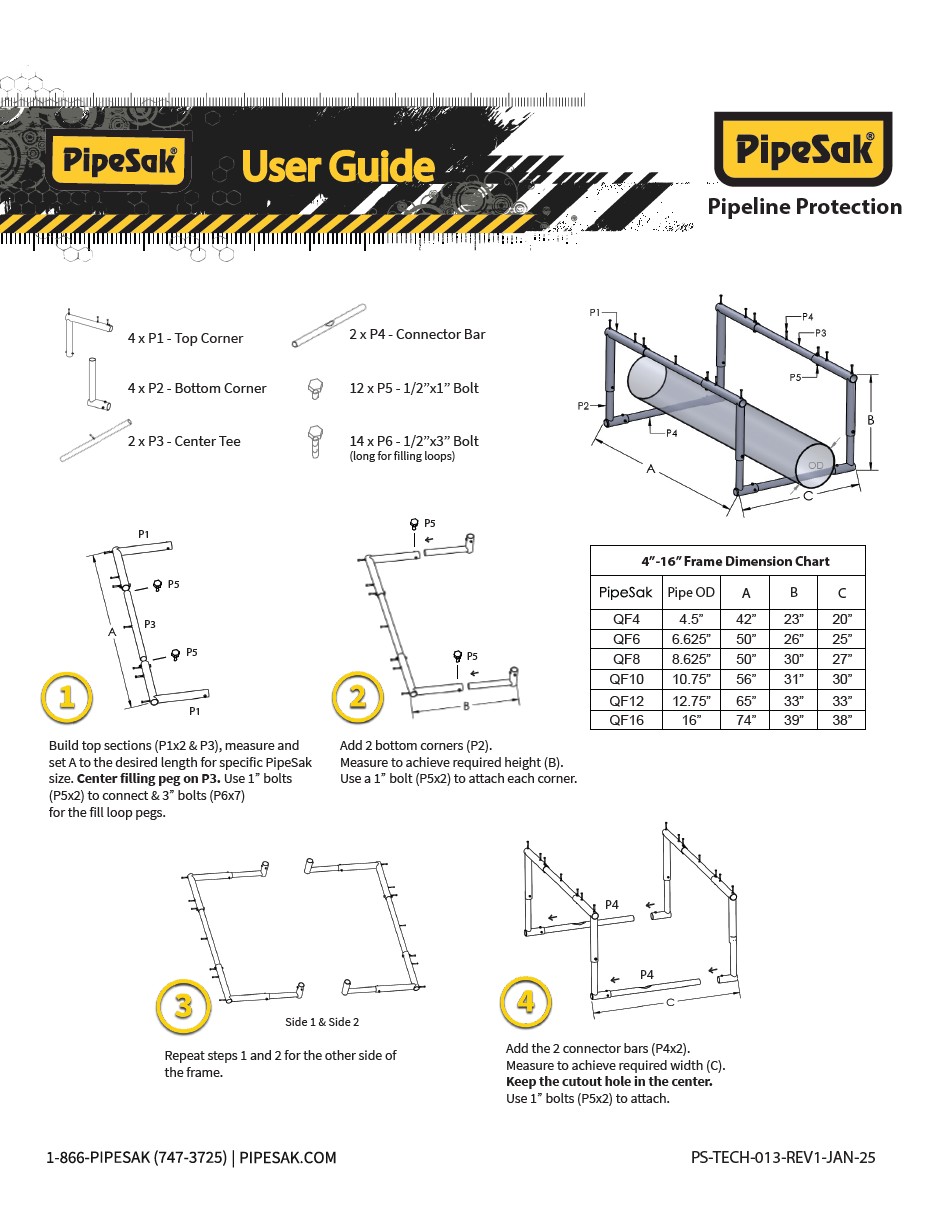

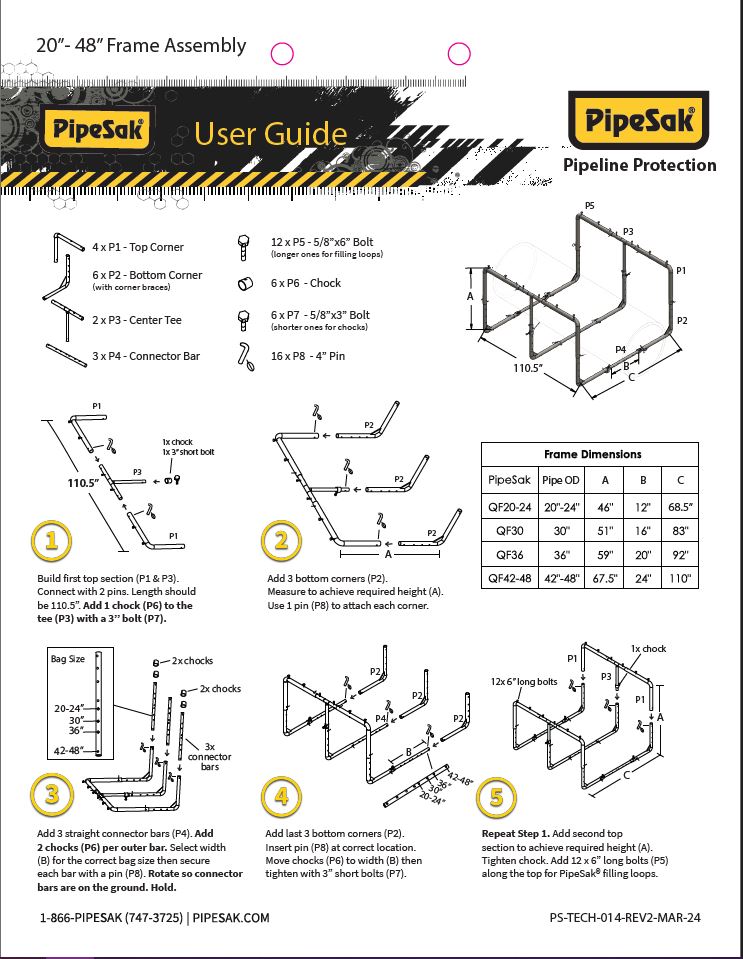

Can PipeSak® Geotextile Pipeline Weight’s (GPWs) be hand-filled? Why would I need a filling frame?

While PipeSak® GPWs can be filled by hand. For larger sizes and/or quantities, the volume of fill material required may make hand-filling impractical.

PipeSak® Filling Frames greatly increase the efficiency of filling PipeSak® GPW’s.

-

Why do PipeSak® Geotextile Pipeline Weights (GPWs) ship empty?

It would not be economically viable to ship filled PipeSak® GPWs across large distances. Instead, PipeSak® GPWs are shipped empty and filled on-site with local aggregate.

PipeSak® does retain stockpiles of filled PipeSak® GPW’s in select locations across the continental U.S., allowing PipeSak® to fulfill time-sensitive orders. If you have an immediate requirement, please contact a PipeSak® representative.

-

Why is there more than 1 size of PipeSak® Geotextile Pipeline Weight (GPW)?

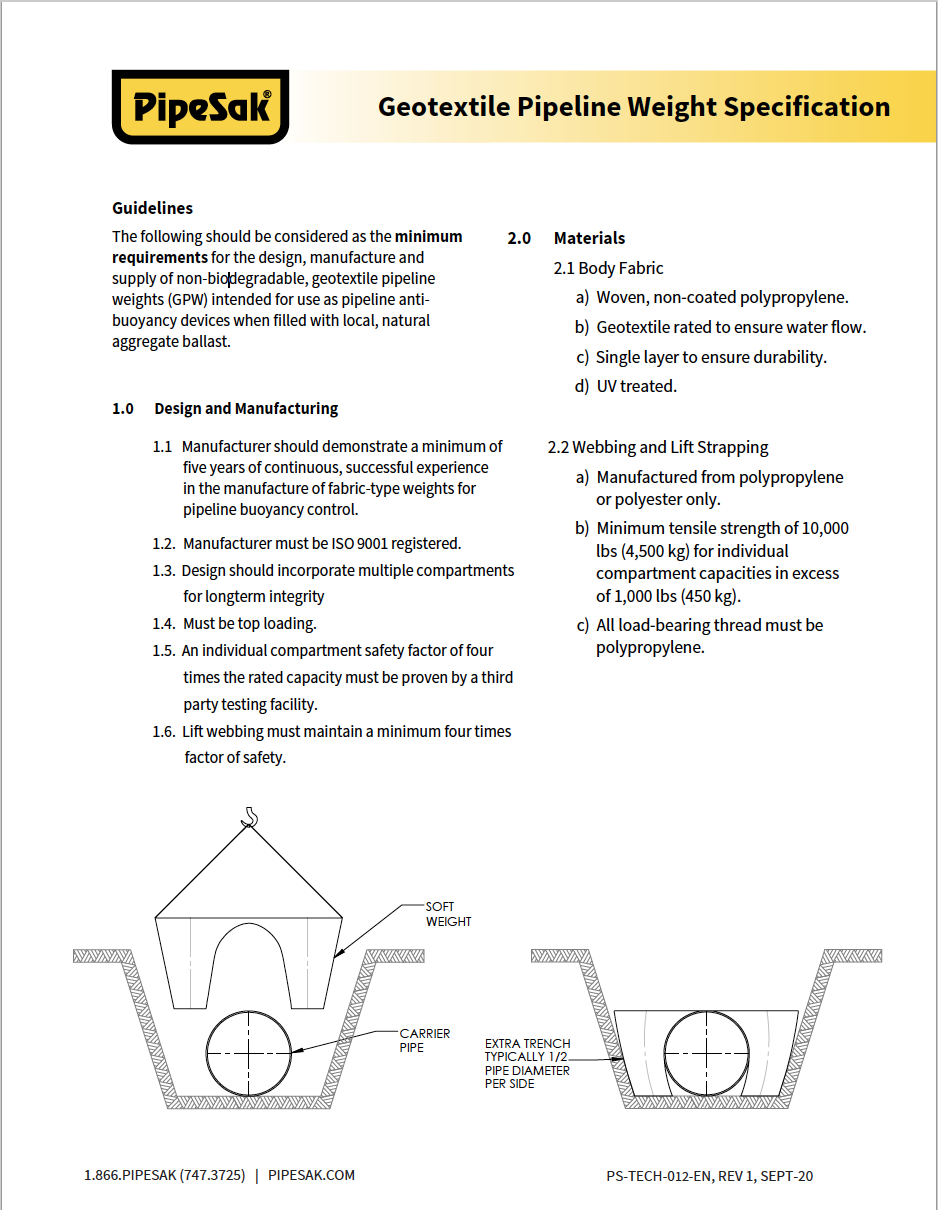

Each PipeSak® GPW is exactly sized to ensure that the weight of the PipeSak® GPW rests on the bottom of the trench (as opposed to on the pipe), with the top fabric of the PipeSak® GPW tight to the the pipeline to restrict uplift.

Additionally, PipeSak® GPWs are designed such that, when filled, the width of the PipeSak® GPW is proportional to the outer diameter of the pipeline. This ensures there is no wasted expenses on unnecessary trench widening required.

-

Can PipeSak® Geotextile Pipeline Weights be made to sit lower on the pipeline to reduce the required depth of cover?

PipeSak® GPWs are designed specifically to be extremely low-profile, with a minimal amount of protrusion above the top of the pipeline.

-

Will PipeSak® Geotextile Pipeline Weights (GPWs) cause pipelines to sink in light soil?

No. PipeSak® GPWs are designed to rest on the bottom of the trench without placing pressure on the pipeline itself, restricting uplift.

-

How many PipeSak® Geotextile Pipeline Weights (GPWs) can PipeSak® fill in a day?

Depending on size, location, and conditions, PipeSak® typically produces between 100 and 200 filled PipeSak® GPWs per day. Production per day can be greatly increased by adding additional filling crews.

PipeSak® filling crews are economical, safe, efficient and have decades of experience. Contact a PipeSak representative to inquire about our filling services and training services.

-

How many filled weights can be hauled per load?

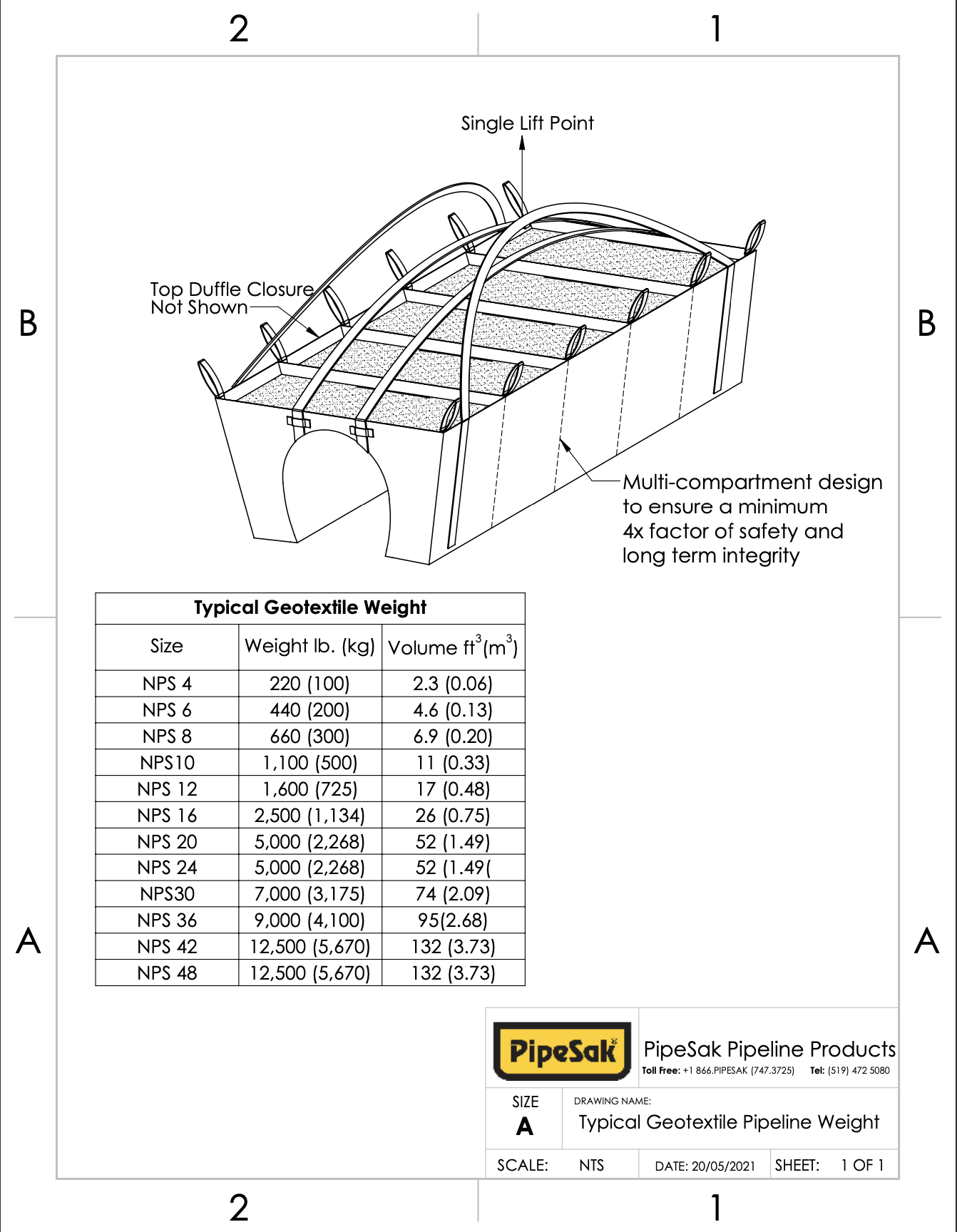

Filled PipeSak® Geotextile Pipeline Weights (GPWs) range in weight between 100kg (220lbs) to 5670kg (12,500 lbs), depending on size.

The number of PipeSak® GPWs which can be hauled per load fluctuates with size, weight, and mode of transportation. A PipeSak® representative would be happy to provide a detailed answer based on your exact requirements.

-

Why is it important to have a woven fabric for geotextile pipeline weights?

The main reason for a woven non-coated fabric is to ensure an easy path for cathodic protection. In addition, todays woven fabrics are engineered to be extremely strong, long lasting and resist any tearing.

PipeSak® GPWs are designed to carry an immense amount of weight safely. To achieve a 5x safety factor, a strong woven material is required.

-

What is the life expectancy of a PipeSak® Geotextile Pipeline Weight (GPW)?

PipeSak® GPWs are made from an inert, non-biodegradable, underground-rated material which ensures that when properly handled and installed to outlast the lifetime of the pipeline.

-

Why use a multi-compartment bag design?

Single-compartment designs have to fully stretch out upon lifting, putting the bags at higher risk of breaking and if there were to be a break all of the weight would pour out resulting in more waste, higher risk of injury and reduced work efficiency. A multi-compartment design not only provides structure and even weight distribution, but also keeps workers safe and maintains long-term functionality. Upon lifting and during installation, if a hole were to develop, a majority of the weight would be withheld inside the bag therefore less waste and less chance of worker injury.

-

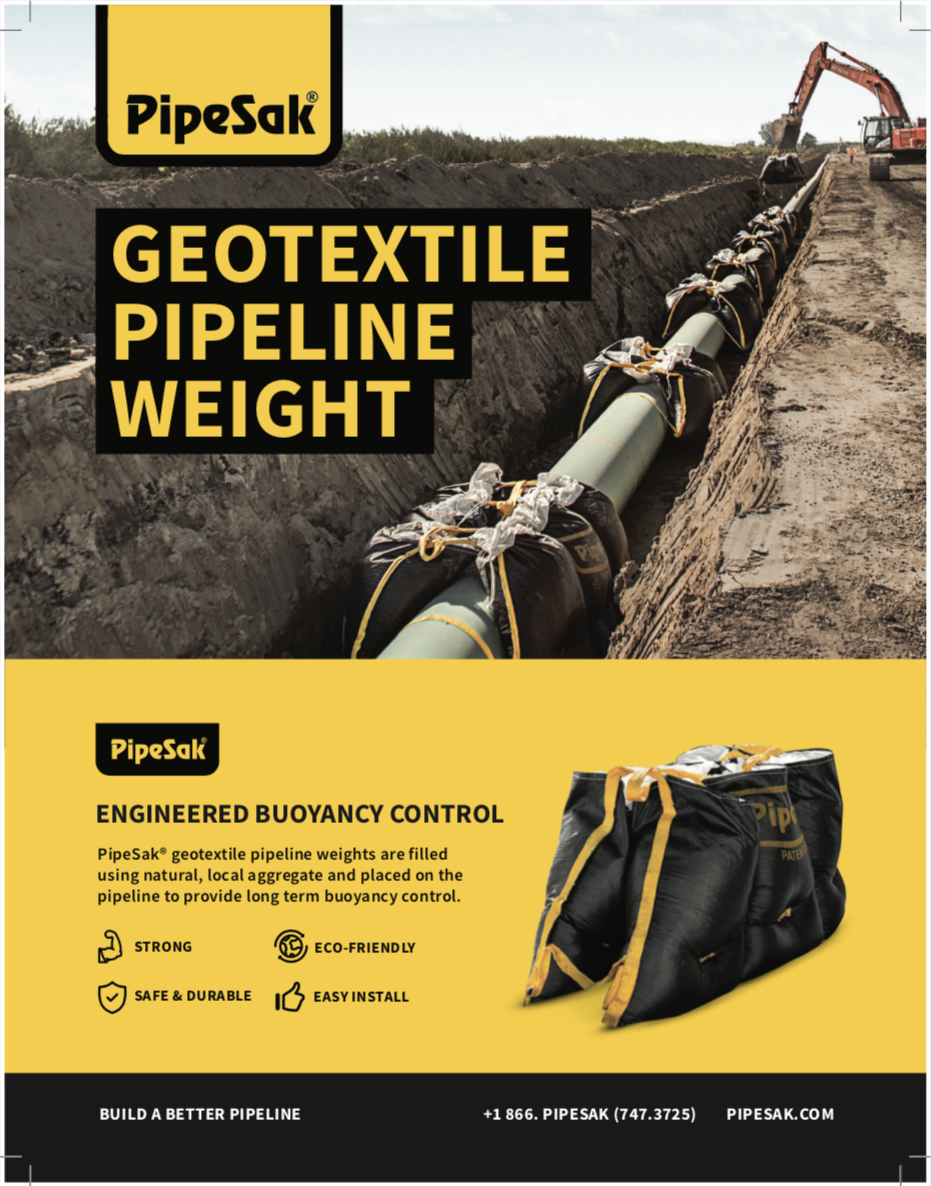

How do PipeSaks® fit in the trench?

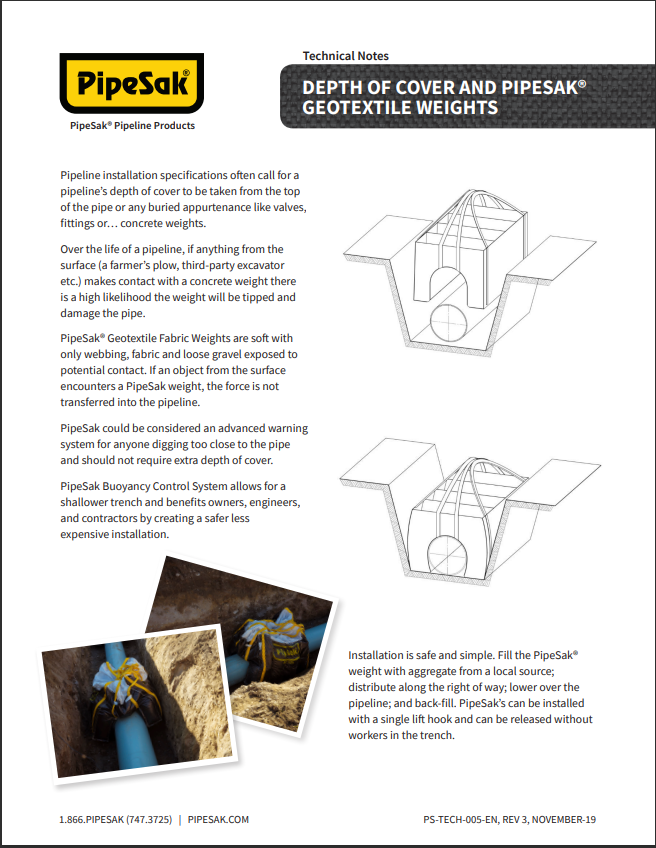

PipeSak® offers an extreme low-profile designed to reduce the required depth of cover and to provide even weight distribution while the top fabric of the weight is designed to fit tightly to the pipeline, restricting uplift. Each PipeSak® pipeline weight is precisely sized to ensure that the weight rests beside the pipe and in some cases even rest on the bottom of the trench rather than on top of the pipe. Additionally, PipeSak® eliminates unnecessary trench widening costs by matching the width of the weight to the pipeline’s outer diameter. The sides of the pipeline weight are shaped as a wedge to reduce the height of the bag to nearly the diameter of the pipe resulting in lessened depth of cover requirements.

-

What is the weight range for filled PipeSak®?

Filled PipeSak® GPWs range in weight from 100kg (220 lbs) to 5670kg (12,500 lbs), depending on the size. The number of GPWs that can be hauled per load will vary with size, weight, and mode of transportation. A PipeSak® representative can provide a detailed answer based on specific requirements.

-

Do you fill PipeSaks®?

Yes – with trained crews, we meet your weighting needs with speed and accuracy for your convenience and to keep your project on schedule. PipeSak® Geotextile Pipeline Weights are designed to be filled close to the site with local materials for maximum flexibility. This on-site filling process also makes transportation easier and more cost-effective compared to concrete weighting options.

-

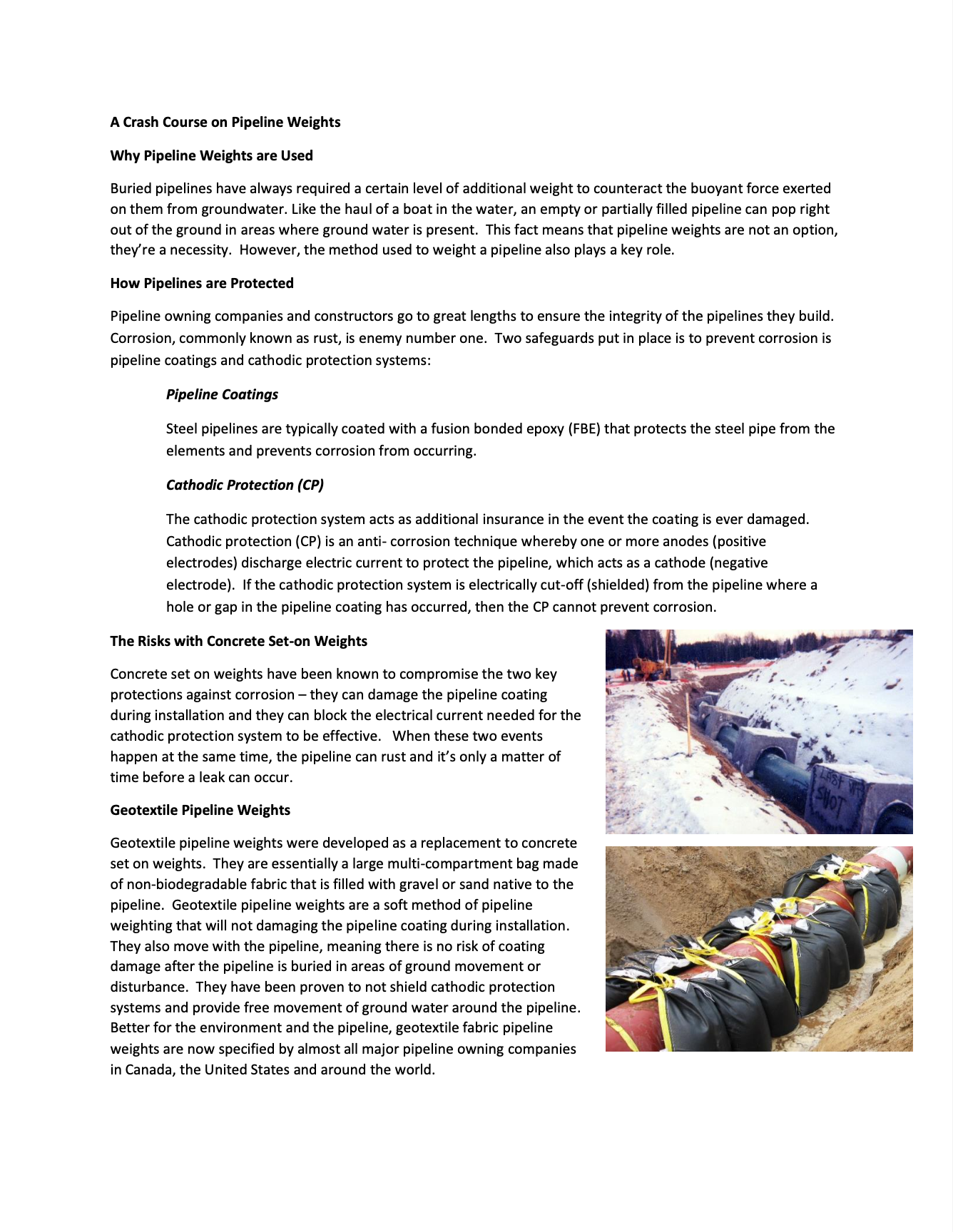

Do pipeline weights interfere with cathodic protection?

Geotextile pipeline weights do not interfere with cathodic protection, as they allow moisture and electrical flow. In contrast, some concrete weights may block CP currents, leading to corrosion risks.

PipeSak® GPWs are compatible with cathodic protection systems and have been validated by third-party corrosion testing. Made from permeable geotextile fabric rated for underground use, they match the permeability of the ballast material inside the bag. The use of a woven non-coated fabric ensures a clear path for water and cathodic protection currents. Modern woven fabrics are designed to be highly durable, long-lasting, and resistant to tearing.

-

What material are PipeSak® saddle bag weights made from?

PipeSak® pipeline addle bag weights are made from an inert, non-biodegradable, underground-rated polypropylene. When properly handled and installed, this material ensures that the pipeline weights will outlast the lifetime of the pipeline they support. This robust woven material is crucial for enabling the PipeSaks® to safely support substantial weight.

-

What should I fill PipeSaks® with?

PipeSak® generally suggests filling the GPWs with clean local aggregate, sand, or gravel, depending on what is most readily available. In freezing conditions, it is advisable to use natural, screened stone aggregate with a consistent size to reduce the chances of freezing.

-

Where can I get PipeSak® saddle bag weights from?

PipeSak® pipeline weights can be shipped empty worldwide and then filled close to the site using local aggregate.

-

How durable are PipeSaks®?

Each component of a PipeSak® is engineered with a minimum 4x factor of safety to meet the rigorous demands of pipeline construction. The fabric and webbing of PipeSak® undergo strict quality control testing to ensure consistency in performance.

-

What are pipeline weights used for?

Pipeline weights prevent buoyancy in buried pipelines, ensuring they remain stable in wet or soft soil conditions. They help counteract uplift forces caused by waterlogged environments.

-

What are the different types of pipeline weights?

The three main types of pipeline weights are:

• Geotextile pipeline weights (e.g., PipeSak®) – Flexible, easy to install, and compatible with cathodic protection.

• Concrete weights – Rigid but heavy; may disrupt cathodic protection.

• Bolt-on steel weights – Adjustable but require more installation time. -

How do geotextile pipeline weights compare to concrete weights?

• Geotextile weights are lightweight before filling, easier to transport and install, and provide even weight distribution.

• Concrete weights are precast, making them heavier to transport, and they may create stress points on the pipeline.