FAQ

-

What is PipeDefender® made from?

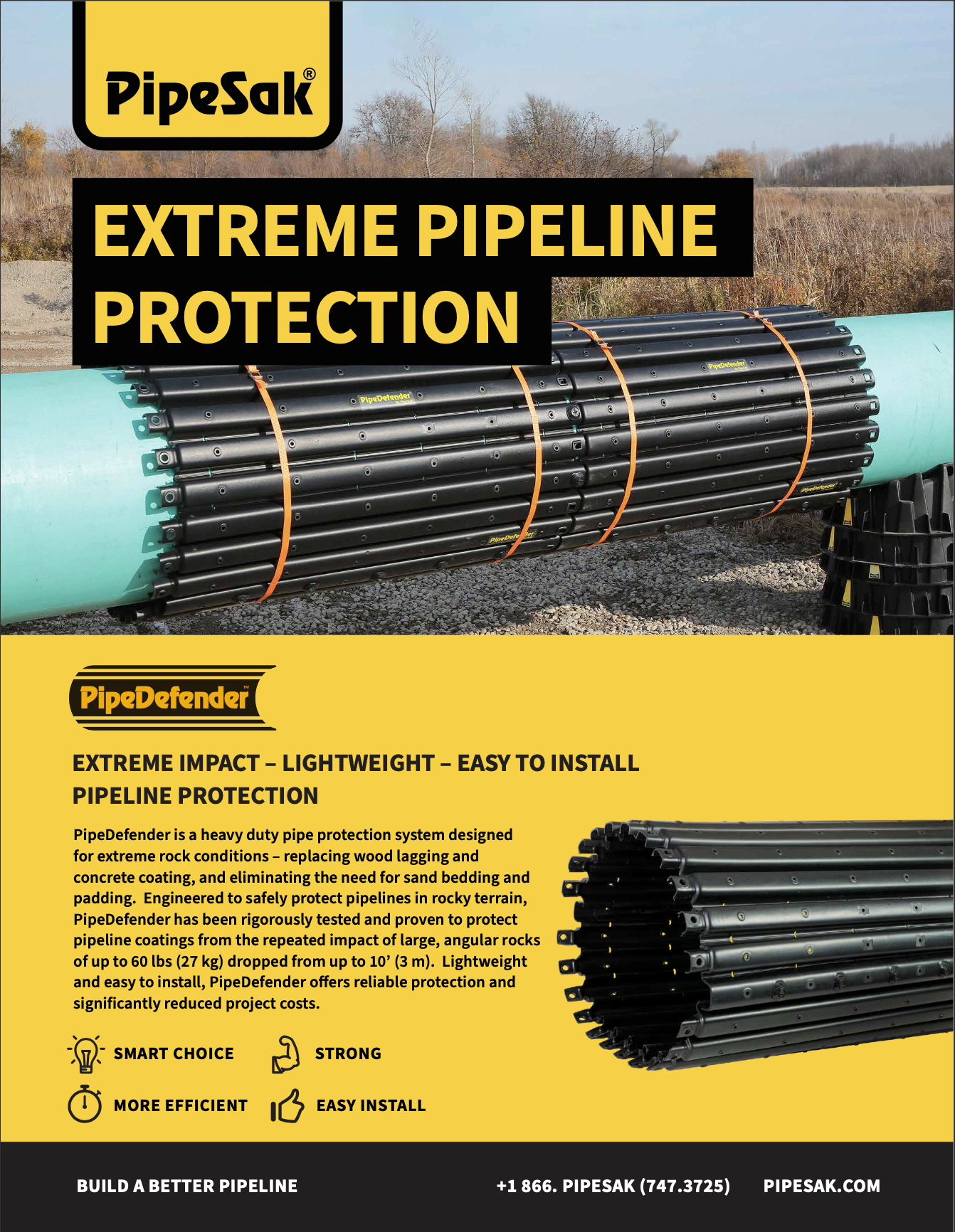

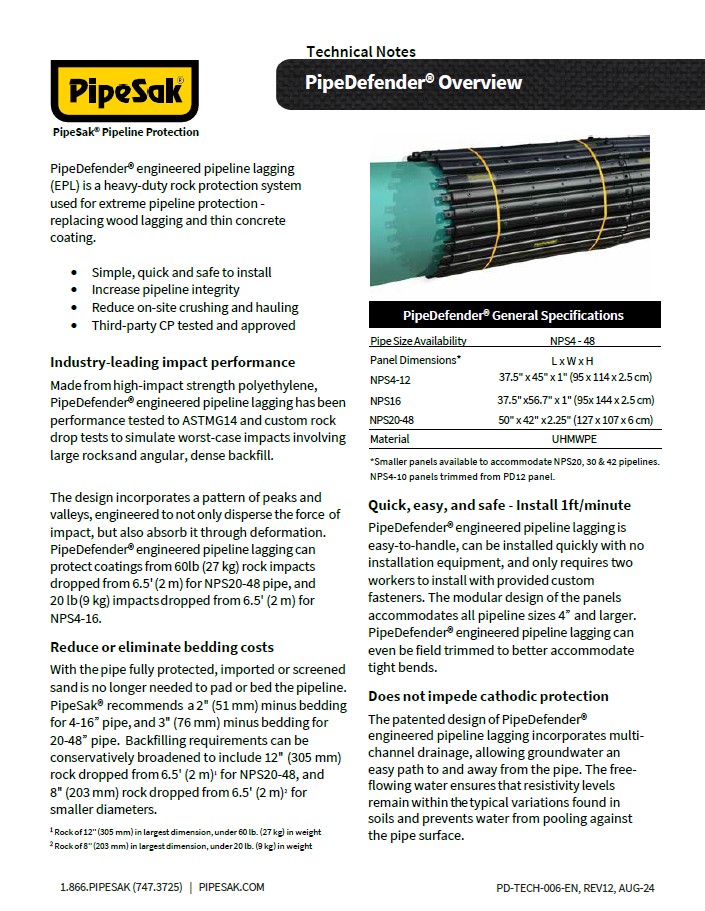

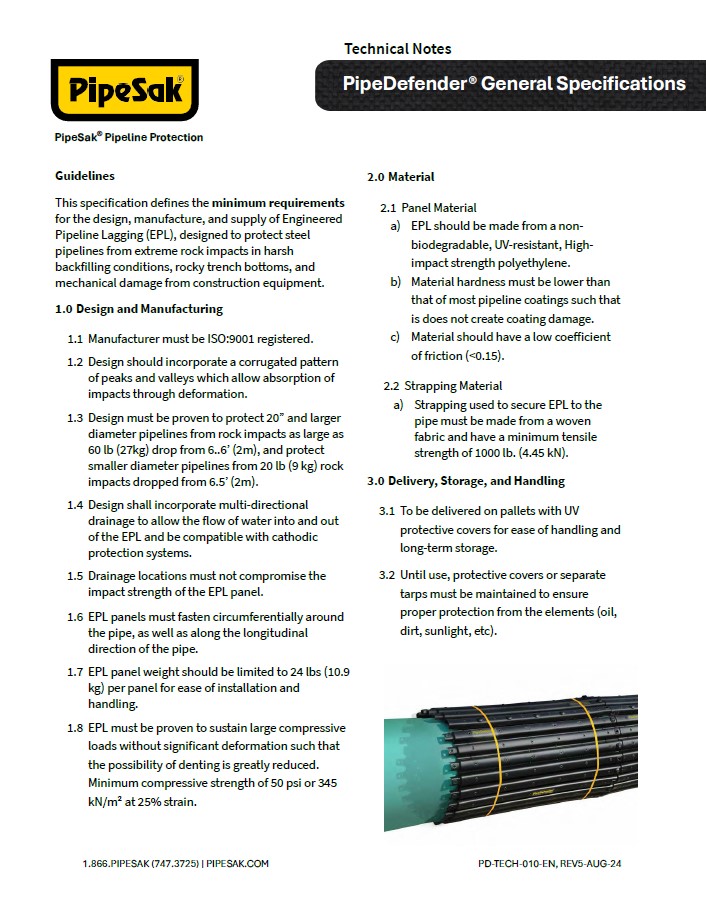

PipeDefender® engineered pipeline lagging is made from high-impact strength polyethylene. The design incorporates a pattern of peaks and valleys to not only disperse the force of impact but also absorb it through deformation providing superior protection compared to traditional wood lagging.

-

What sizes can PipeDefender® be purchased in?

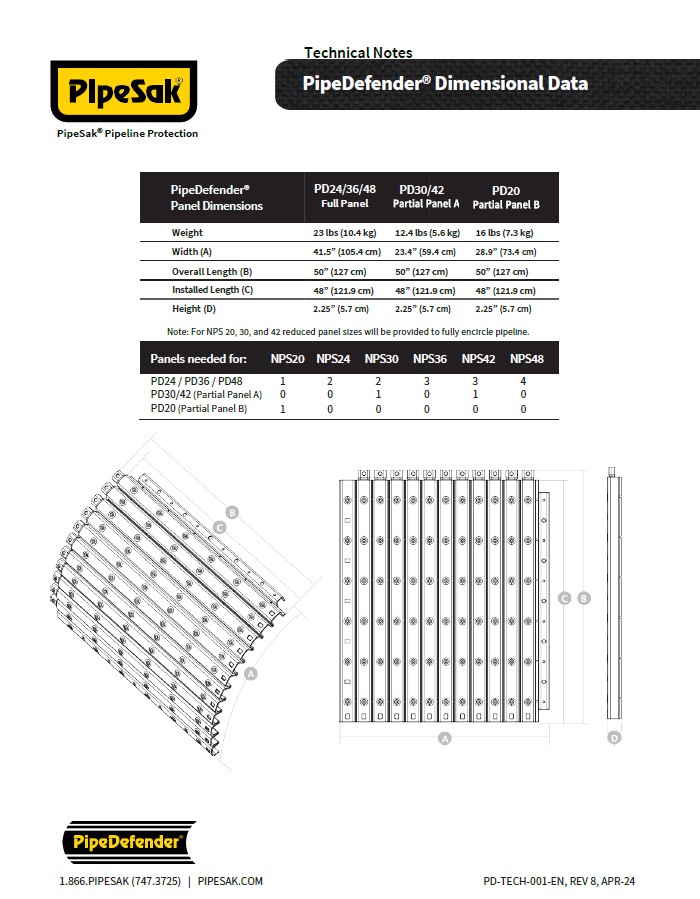

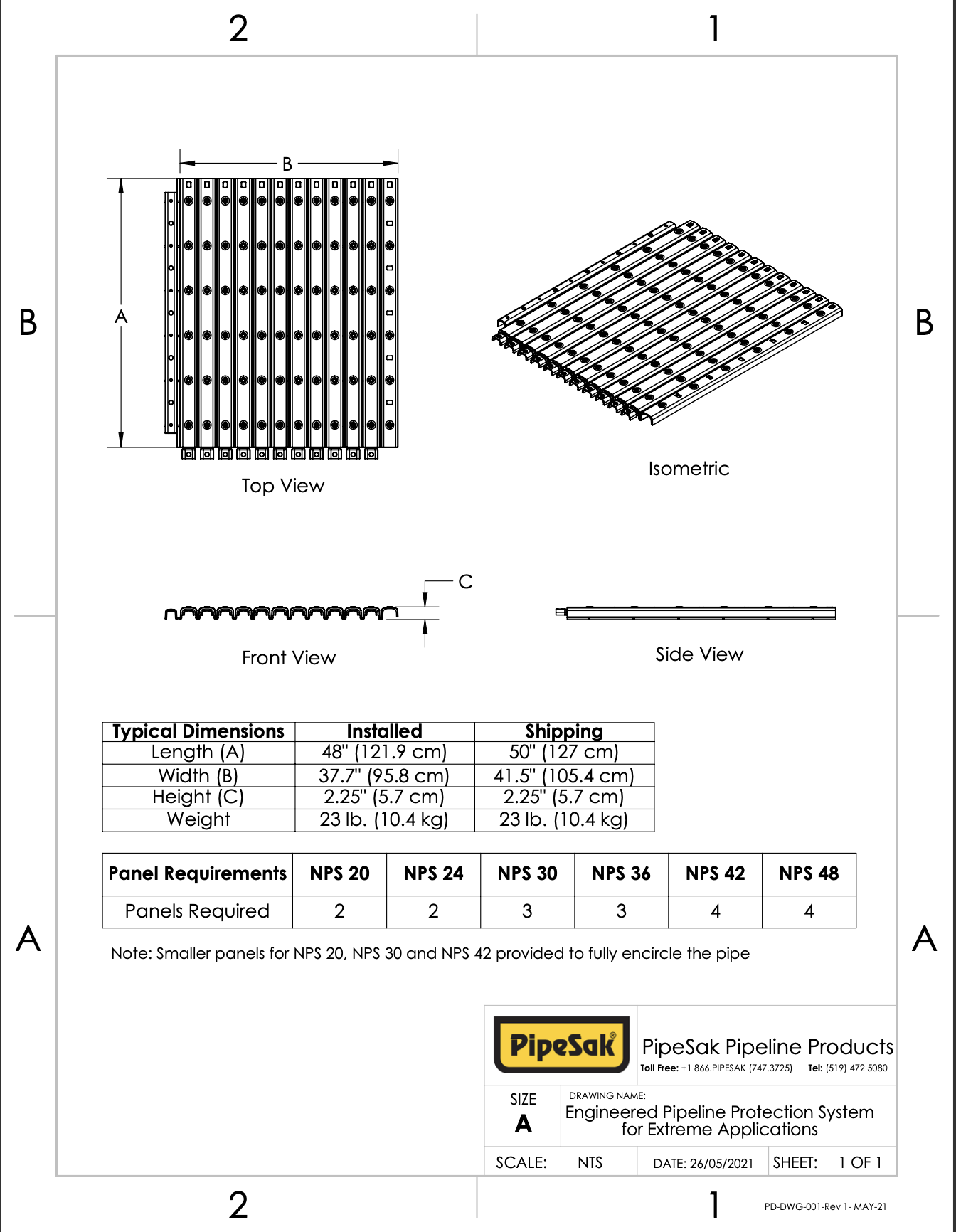

PipeDefender® is available for 4"-48" diameter pipe with panels up to 38” wide x 48” long panels that can easily be connected with seamless, overlapping teeth to fully encircle the pipe for no-compromise protection.

-

What’s the difference between traditional wood-lagging and PipeDefender®?

PipeDefender® is an extremely lightweight engineered pipeline lagging system that is easy to handle, easy to transport and requires no equipment to install it. PipeDefender® provides extended protection due to its polyethylene composition compared to using a natural wood material that will decompose. PipeDefender® offers the most robust and long-term protection while reducing handling, shipping, and labor costs.

-

How do you install PipeDefender®?

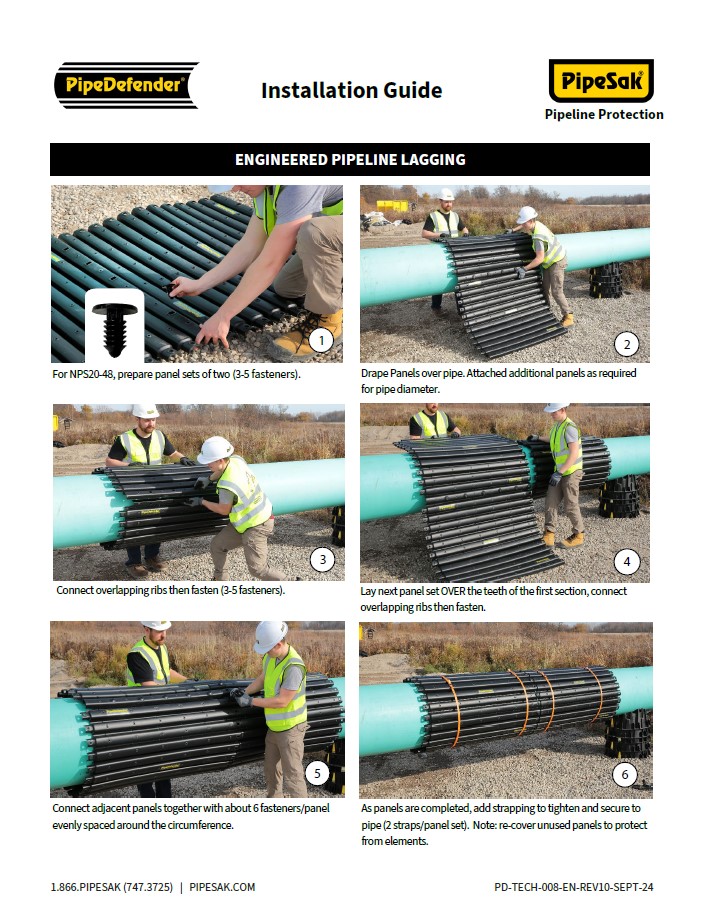

At only 23 lbs per panel, PipeDefender® is easy to handle and can be installed quickly. The interlocking design makes installation with two workers simple. Custom QuickZip™ fasteners come supplied with every order. The modular design of the panels accommodates all pipeline sizes 20" and larger. PipeDefender® can even be trimmed onsite to better accommodate tight bends.

-

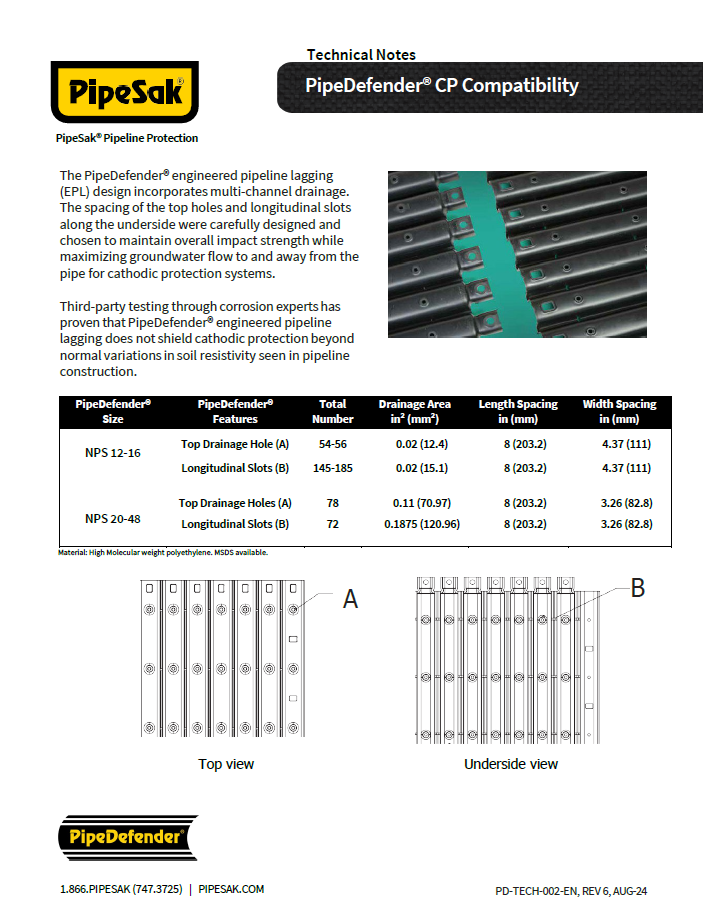

Will PipeDefender® interfere with cathodic protection systems?

No. The patented design of PipeDefender® engineered pipeline lagging incorporates multi-channel drainage, allowing ground water an easy path into AND out of PipeDefender®. The free-flowing water ensures that resistivity levels remain within typical variations found in soils, and prevents water from pooling against the pipe surface.

-

Can engineered pipeline lagging be used on different size pipes?

Yes – PipeDefender® panels can be easily modified in the field to fit nearly any pipe size from 4″ to 48″ in diameter, including accommodating bends in the pipeline. The panels come in two sizes: one designed for pipes 20” and larger, and another for pipes 16” and smaller, featuring smaller ribs that maintain the same level of protection. The larger size has significantly larger ribs with a height of over 2”, while the smaller size has more ribs for enhanced protection around smaller pipes, with a height of 1”. These panels are available in widths up to 38” and lengths up to 48”. The overlapping teeth design ensures complete encirclement of the pipe, providing comprehensive protection.

-

How do I install engineered pipeline lagging?

PipeDefender® panels are designed to be user-friendly and fast to install. Each panel weighs only 23 lbs (10.43kg) making it easy to handle. The interlocking design allows for simple installation with just two workers. No installation equipment required: Custom fasteners are provided with every order and can be easily installed by hand to secure panels of PipeDefender® together and around the pipe.

-

Does PipeDefender® work with cathodic protection?

Yes, PipeDefender® is designed to be compatible with cathodic protection systems. Its patented multi-channel drainage design ensures that groundwater flows to and away from the pipe to maintain resistivity levels within typical soil variations. Check out our PipeDefender® cathodic protection specifications.

-

How does PipeDefender® compare to thin concrete coating and soil padding in terms of equipment needs?

PipeDefender® is an optimal replacement for thin concrete coating as well as soil padding due to the reduction in equipment needs. Concrete is inherently heavy, requiring more trucking, heavier equipment, and more matting. The need for padding machines, crushing machines, and trucks of sand can be dramatically reduced or eliminated by using PipeDefender®.

-

What can engineered pipeline lagging be used for?

With it’s unique and durable peaks and valleys designed to absorb impact through deformation, PipeDefender® is being used in casings, bores and for drilling applications. It maintains its structure, preventing collapse and ensuring the pipe remains isolated from its casing but is flexible enough to absorb impact and abrasion when needed.

With its low coefficient of friction, PipeDefender® slides smoothly through rocky bores even without casing pipes. Its corrugated design facilitates the easy application of flowable fills after pipe installation. Additionally, PipeDefender® is suitable for protecting foreign line crossings, underwater applications, and long-term exposed pipes.