When it comes to pipeline protection, you need to be able to have full confidence in the products you’re using to safeguard your project from the elements – both during the pipeline’s installation and over its entire lifetime. Rockshield products are engineered to give you that confidence. The premier rockshield materials, like the ones offered by PipeSak®, go above and beyond protection with innovative designs and easy installation. These products not only protect the pipeline from the harshest elements, but also maximize on-site productivity and efficiency.

To help you become more familiar with rockshields as well as the different types of products and materials available, we’ve compiled helpful and informative answers for a few of the most frequently asked rockshield questions.

What is a pipeline rockshield?

Rockshield is a category of pipeline protection product designed to safeguard a pipeline’s coating from damage caused by impact during backfilling in rocky trenches. Rockshield also aims to limit wear on the coating that’s caused by pipeline movement underground during operation.

Rockshield pipeline protection products are available in a range of materials, from wraps to concrete coating, that work to effectively prevent denting, scratching and abrasions in rocky conditions and harsh climates. Crucially, rockshield products should be compatible with cathodic protection systems that prevent corrosion on the surface of a pipeline.

With expertise in oil and natural gas pipelines, as well as water and hydrogen, PipeSak® has been supplying the pipeline industry with innovative engineered protection products for more than 30 years. Our industry-leading rockshield products – RockStop® and PipeDefender® – offer superior impact resistance, effective protection in extreme conditions and easy, cost-effective installation.

What are the different types of rockshield?

Rockshield products come in a range of materials and sizes. Each rockshield offers different levels of protection as well as various benefits and drawbacks, depending on the material.

Below we’ve broken down five types of rockshield and outlined what you need to know about each product.

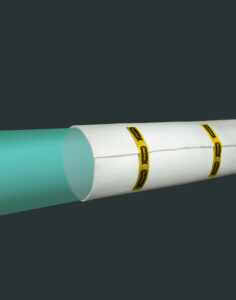

Wraps – Typically made from lightweight plastic material, rockshield wraps like PipeJacket® and RockStop® offer good impact and puncture resistance that is durable and flexible in various conditions. Wraps can typically be installed three ways, depending on pipeline diameter size: “cigarette wrap” or longitudinal method, latitudinal method or spiral method. Rockshield manufacturers usually provide installation guides that help ensure the products will deliver maximum protection.

Heavy-duty protection systems – Designed for pipeline protection in extreme conditions, these systems are typically more resistant to heavier impact than rockshield wraps. PipeDefender®, for example, can withstand boulders that weigh more than 60 pounds when dropped from 10 feet.

Sand or screened backfill – Known as “padding,” the use of sand or screened backfill requires the material to be brought in from elsewhere or the use of a padding machine to sift large rocks and other potentially damaging material out of backfill. Sand padding has the potential to migrate or washout with seasonal water tables and can be inconsistent, creating opportunities for holidays (a defect in the pipeline coating).

Wood lagging – Thin, narrow pieces of wood are strapped around the outside surface of a pipeline to provide mechanical protection from impact and abrasion, in rocky conditions. The wood lagging is usually installed prior to the backfilling operation. Due to the weight of the material, wood lagging can be difficult to install and transport, especially to remote areas. It also requires additional labor, machinery, time and cost when compared to other rockshield products like RockStop® and PipeDefender®.

Concrete coating – A thin layer of concrete is applied to the pipeline off-site, transported to the project site and buried in the trench. Like other rockshields, the concrete works to protect the coating during the backfill and from damage caused by pipeline movement during operation. Concrete coating often has long lead times and, like wood lagging, requires more labor, machinery, time and cost than other rockshields.

When do you need a rockshield?

Rockshield products are needed for pipelines that run through rocky conditions, requiring protection for pipeline coating. Rockshield offers protection during both the backfilling operations, when large rocks and dense backfill are dropped onto the pipeline, and over the long term, keeping hard objects in the backfill away from the pipe coating during operation of the line.

As an alternative to other pipeline protection methods like concrete coating, rockshield products like those developed by PipeSak® are lightweight and easy to install, resistant to high temperatures and flexible in low temperatures, and can be customized to specific pipeline diameters.

How much impact protection do rockshields offer?

The impact protection offered by rockshield pipeline protection products is determined by several tests conducted for tensile strength, impact strength and low temperature brittleness (and others, depending on the product) to ensure the rockshield meets ASTM International standards.

When it comes to impact pipeline protection, all three of the PipeSak® rockshield products – PipeJacket™, RockStop® and PipeDefender® – offer superior impact resistance.

PipeDefender®, in particular, is a revolutionary rockshield product. Made from high-impact strength polyethylene, PipeDefender® has been performance tested to ASTM G14 and passed custom rock-drop test worst-case impacts involving large rocks and angular, dense back fill. PipeDefender® is rated to withstand boulders more than 60 pounds when dropped from 10 feet.

Are there heavy-duty rockshields?

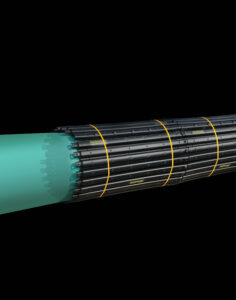

Yes – PipeDefender® is an innovative heavy-duty rockshield product that is designed specifically for pipeline protection in extreme conditions.

Developed as an alternative to wood lagging and thin concrete coating, PipeDefender® is the only heavy-duty, lightweight rock shield on the market today. With a unique peak-and-valley design, PipeDefender® is made to disperse force and absorb deformation to provide industry-leading impact protection.

With a weight of just 23 pounds per panel, PipeDefender® eliminates the need for heavy, cumbersome wood lagging while its streamlined installation process allows two workers to install up to one foot per minute as opposed to time-consuming concrete coating.

Are rockshields easy to handle and install?

Thanks to continued innovations throughout the pipeline protection industry, rockshields are now lighter and easier to install. While products like wood lagging and concrete coating remain common, both are time-consuming to install and difficult to transport. As a result, newer and more innovative products have become popular with companies installing pipelines of all types.

Rockshield installation methods depend on the type of material used. For wraps like PipeJacket™ and RockStop®, there are three typical installation methods, depending on pipeline diameter size: “cigarette wrap” or longitudinal method, latitudinal method or spiral method.

RockStop® is up to 50 percent lighter than other rockshields and its material compound makes the product soft on the installer’s hands and easy to handle. Plus, PipeSak®’s QuikStrip™ fasteners make installing the pipeline wrap faster and safer than other rockshields.

The installation methods of heavy-duty rockshield materials like PipeDefender®, wood lagging and concrete coating all differ. Concrete coating applied to the pipeline off-site then transported while wood lagging is transported to the site where it is strapped to the pipeline.

PipeDefender® is significantly lighter than both wood lagging and concrete coating, plus its panels come in four-foot lengths, making transportation and installation of the revolutionary heavy-duty rockshield much less challenging than competing products. PipeDefender® is quickly and easily installed by just two workers using its interlocking design and PipeSak®’s patented QuickZip™ fasteners for added security. PipeDefender® can also be trimmed for tight bends and appurtenances.

Each of the PipeSak® rock shield products – PipeJacket™, RockStop® and PipeDefender® – are custom-made to fit any pipeline diameter.

Where do you buy a rockshield?

Purchasing rockshield products starts with contacting a pipeline solutions manufacturer like PipeSak® to get a quote for your next project. This process usually requires you to provide company information as well as further details about the pipeline project the rock shield will be used on, including location.

The experienced team at PipeSak® fully understands the need for safety and longevity of all pipeline projects, and we work tirelessly to ensure our products meet your standards, stay within your budget and offer reliable support that lasts.