PipeSak’s Role in Energy Infrastructure Growth

by Meghan Connors, President of PipeSak® Inc.

Introduction

To meet the growing demand of Ontario, Quebec and Eastern US energy markets, Union Gas, a major Canadian natural gas company, has embarked on numerous infrastructure projects to increase the transmission capacity of the Dawn Hub – the second largest liquid natural gas trading hub in North America. PipeSak Incorporated has supplied various pipeline stability, protection and support products to assist Union Gas in the construction of two key pipelines related to the Dawn Parkway Expansion – the 48” Brantford to Kirkwall Project (2015) and the 48” Hamilton to Milton Pipeline (2016).

The Dawn Hub and Dawn Parkway

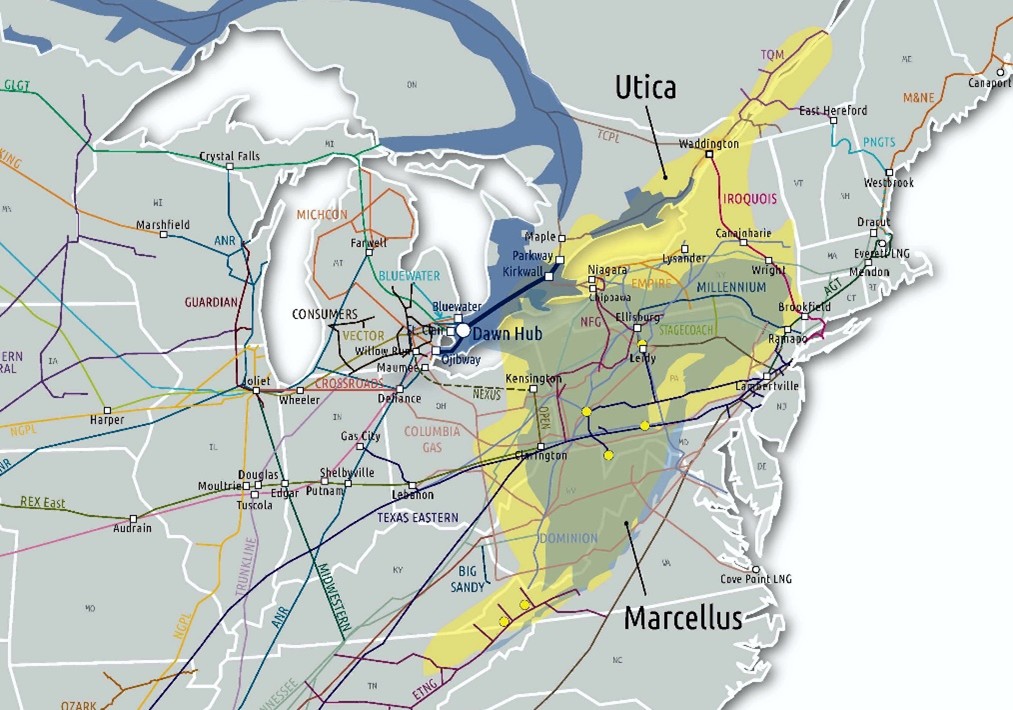

Union Gas is a major Canadian natural gas storage, transmission and distribution company based in Ontario, Canada. The Union Gas Dawn Hub is the largest integrated underground natural gas storage facility in Canada and the 2nd most physically traded hub in North America. The Dawn Hub is strategically located in Southwestern Ontario only 300 km (186 mi) from the Marcellus and Utica shale basins of the U.S., which is expected to supply over 40% of the natural gas to the Dawn Hub by 2023. To service the Dawn Hub, Union Gas’ Dawn Parkway System consists of 225 kms (140 mi) of parallel 660 mm (26”), 864 mm (34”), 1067 mm (42”) and 1219 mm (48”) OD pipelines as well as four mainline compressor stations: Dawn, Lobo, Bright and Parkway.

Upstream infrastructure expansion projects in the U.S., such as the NEXUS gas transmission system, the ANR East Project, the Rover Pipeline and several others, are expected to bring new and affordable sources of gas into the Dawn Hub. Union Gas owns and operates four mainline compressor stations that provide over 622,414 horsepower to 3014 miles of pipe and market coverage for approximately 10 million customers in Canada and the northeast U.S. The Dawn Parkway expansion project is intended to increase capacity from the Dawn storage facility to the Parkway Compressor station located near Toronto Ontario, where gas is then moved to markets in the Eastern Canada and the Northeastern US (see Figure 1).

This expansion project is in response to increasing supply and storage needs to meet growing demand. The pipeline and compressor construction projects are scheduled over a three-year period – 2015, 2016 and 2017. When all three phases of the expansion are complete, the Dawn-Parkway System capacity will have increased by 1.3 PJ/d (1.2 Bcf/d) for a total capacity of 8.2 PJ/d (7.6 Bcf/d) – making it one of the most robust pipeline systems in North America.

Union Gas has been operating in Ontario for over 100 years and is committed to minimizing the impact of their projects and operations on the environment. Union Gas is well known for their safety-oriented culture and has made safety a top priority. Their experienced pipeline contractors, such as Banister Pipeline Construction, are committed to using local resources and materials when possible, contributing to the overall economic vitality of the region.

PipeSak Pipeline Products and Engineering Services has assisted Union Gas and their contractor, Banister Pipeline Construction, by supplying engineered safe buoyancy control, pipeline support and pipeline protection products for two of the pipeline expansion / looping projects – the 2015 Brantford Station to Kirkwall Compressor Station, 14 km (8.7 mi) of 1219 mm (48”) OD, 11.7 mm (0.460”) WT and the 2016 Hamilton Station to Milton Station, 20 km (12.5 mi) of 1219 mm (48 “) OD, 15.7 mm (0.618”). Each pipeline brought forth some unique construction challenges. PipeSak worked closely with both Union Gas engineers and Banister Pipeline Construction to help overcome these challenges by offering innovative and cost-effective solutions.

Pipeline Construction Obstacles

Both the 2015 Brantford to Kirkwall and 2016 Hamilton to Milton pipelines crossed through densely populated and environmentally sensitive areas where safety, speed of construction and limited environmental and social impact were of utmost importance. Some of the more challenging obstacles included:

Rock and cobble filled trenches, particularly near the eastern end of the Brantford to Kirkwall station where the pipeline crossed the Niagara Escarpment, required diligent pipeline protection to ensure pipeline integrity was maintained.

Crossing of environmentally sensitive wetlands and a wildlife preserve demanded that the pipeline contractor limit the environmental impact of construction and return the wildlife reserve to its original state in the least disruptive and quickest way possible.

High water tables plagued both projects, and was often difficult to control due to the rock involved. The eastern section of the Brantford to Kirkwall area was particularly challenging. Not only did it cut through the Niagara Escarpment, a natural rock formation, but the pipeline corridor went through what is known as a ‘recharge area’ for the surrounding land. This meant that any precipitation within the area naturally collected in the groundwater, making trench de-watering nearly impossible.

Parallel and crossing hot lines had to be safely navigated. The Dawn Parkway system consists of four pipelines: 660 mm (26”), 864 mm (34”), 1067 mm (42”) and 1219 mm (48”). The importance of the system meant that the lines had to remain in service during construction, adding an additional layer of caution to the construction projects.

Major road and highway crossings were inevitable during the construction of both pipelines. Union Gas and Banister Pipeline Construction were committed to limiting disruption caused by road closures and to maintaining access to businesses along the pipeline routes. To accomplish this, the pipeline was bored or drilled directly underground wherever possible for road, rail and stream crossings.

Inland lake crossing, which required the pipe to be concrete-coated and dragged into position. The inland lake, known as Isley Lake, was manmade with a water proof clay layer. The Brantford to Kirkwall pipeline crossed the Isley Lake, which required the pipe to be precision-bent and concrete-coated prior to installation.

Closeness to residential areas highlighted the need for safe, tight and expedient construction practices. Not only was the pipeline corridor close to many major roads, businesses and homes, but also several schools. Minimizing the impact of construction on the surrounding population required the contractor to be prepared for any unseen construction obstacles.

Tight construction timelines due to the nature of the Canadian climate meant that construction had to be on schedule, at all costs. Any delays due to weather or unseen obstacles had to be made up for before the Canadian winter began to set in – which can happen as early as October in Southwestern Ontario.

PipeSak Pipeline Projects and Engineering Services was brought on to the project in the early stages to assist with the buoyancy control design, in-trench pipeline support through areas of rock, and pipeline stringing on the ROW. While working closely with the design engineers and pipeline contractor, PipeSak also developed a new pipeline protection system for under crossings that was utilized on the 48” Hamilton Station to Milton Station project with much success.

Buoyancy Control Design

Buoyancy control was a large concern throughout both projects. When exposed to groundwater, a NPS48 pipeline will create an uplift force of over 1200 kg/m (806 lb/ft) – far exceeding the weight of the pipeline. PipeSak’s innovative, woven geotextile fabric pipeline weights are each designed to contain 5671 kg (12,500 lbs) of local, natural stone or sand ballast. For both the 2015 and 2016 projects, PipeSaks were filled using aggregate native to the pipeline corridor. This became especially important in environmentally sensitive where the use of foreign materials, such as concrete coating, should be limited. The use of PipeSaks assisted Union Gas in their mandate to minimize the environmental impact of pipeline construction (see Figure 2).

To achieve the required buoyancy control, with a margin of safety, PipeSaks were spaced at 3.6 m (11.8 ft) intervals. For the inland lake crossing, approximately 204 mm (8”) thick, steel reinforced concrete coating was utilized and the pipeline was dragged into position. PipeSaks were then used on the approaches. A portion of the project incorporated a major groundwater recharge for the surrounding area – which made the crossings of small creeks and rivers difficult. When opened up, these insignificant creeks turned into ever increasing bodies of water – necessitating much more buoyancy control and rock protection than originally anticipated. PipeSak geotextile weights can be quickly filled and ready for use in minutes, helping the contractor to cope with these unexpected situations and keeping the tight construction timeline on schedule.

Pipeline Support Solution

With trench water being difficult to contain, the bottom of the pipeline required protection prior to lowering-in. Due to the high water table, compacted sand was not an option. Likewise, foam pillows will float out of position and do not have the load bearing capacity required. PipePillo’s are designed to have an extreme weight bearing capacity and, being slightly buoyant positive, were the perfect solution for this difficult situation. The PipePillo design incorporates a patented dual frustoconical shape which is able to transfer extreme loads very effectively through to consolidated or virgin soil beneath. PipePillos are manufactured from high strength polypropylene resins which are environmentally inert yet softer than most pipeline coatings. In addition, PipePillo’s many cavities help to reduce any cathodic shielding. Although PipePillos are designed to be slid into place just prior to the pipe installation, in this wet, rocky trench they were instead tied to the pipe prior to lowering in (see Figure 3). With an ultimate load bearing capacity of 38,400 kg (84,658 lbs) per PipePillo, PipeSaks could then be installed directed over the pipeline at each PipePillo location – securing the pipeline from both the rocky trench bottom and buoyant forces.

An additional benefit of PipePillos that is being realized by the pipeline industry, and was incorporated into this project, is their ability to help the pipeline resist ovality. With today’s large diameter, high yield strength pipelines, D/t ratios are often exceeding 85, where ovality can often be a concern. When placed at their standard spacing of 4.5 m to 9.1 m (15 ft to 30 ft), PipePillos help the pipe to resist ovality even better than continuous compacted sand bedding. Sand bedding can shift under load and allow ovality to occur. On the 2016 section, PipePillo’s were used to support and protect the 1219 mm (48”) OD pipeline as it left a highway bore and immediately ascended an adjacent hill. The loading at the base of the hill was expected to be extreme and a series of stacked PipePillo’s were used to protect against ovality (see Figure 4).

On the 2015 section, PipePillo’s were also trialed as a replacement for wooden skids. When rotated and stacked PipePillos can be used outside of the trench as a safe pipe support during the stringing and welding process. PipePillos can be stacked in a stable extended mode by rotating them by 1/8, adding 6” of height to each stacked PipePillo (see Figure 5). Using PipePillos in place of wooden cribbing is faster, cheaper, and requires less labour. As an added benefit, PipePillos can be reused over and over, stacking tightly for storage and transportation to the next jobsite. Following welding, PipePillo’s are then on hand for use as in-trench supports.

Pipeline Undercrossings

Since the new 1219 mm (48”) OD pipeline being installed on the 2016 Hamilton Station to Milton Station was a looping, under-crossings of the existing 660 mm OD, 864 mm OD, and 1219 mm OD (26”, 32” and 48”) pipelines was frequent. For one of the earlier built up areas wood lagging was utilized to protect the pipe. Wood lagging incorporates the temporary covering of the exposed pipelines with 2×4 wood slats, which are cabled together then draped over and banded to the pipeline. Wood lagging offers extreme impact and abrasion resistance – but this comes at a cost. The installation of wood lagging is an extremely labour and equipment intensive process. PipeSak engineers took this opportunity to custom-design a replacement for wood lagging in the form of a light weight, high ilightweightmpact resistant pipe wrap.

PipeSak’s high-energy absorbing pipe wrap was utilized on later pipeline under crossings (see Figure 6). PipeSak engineers designed the wrap to be tough, highly visible, and simple to install. Replacing wood lagging for the PipeSak wrap afforded the contractor savings in initial purchase cost as well as installation costs. PipeSak’s newly designed high-impact wrap requires only two labourers to install and no equipment. In addition to the cost savings, the PipeSak wrap is fast and simple to install, saving the contractor invaluable time on a tight construction schedule.

Conclusion

The expansion of the Union Gas Dawn – Parkway system is a strategic and important project for both upstream natural gas suppliers and downstream natural gas consumers. The three-year expansion project, scheduled to be completed in 2017, will provide improved access to high qlow-costuality, low-cost natural gas resources, an important factor in the overall energy security of North America.

Both the 2015 Brantford to Kirkwall and 2016 Hamilton to Milton pipelines crossed through densely populated and environmentally sensitive areas creating unique and challenging construction conditions. Thorough design engineering, robust risk assessments and precision construction techniques were required to ensure the projects were completed on time with as little disruption as possible. Both pipelines were completed successfully and are now in service, adding value to Union Gas Dawn Parkway system.

PipeSak Pipeline Products and Engineering Services believes that everything that touches the pipe should be engineered for safety and in pipeline integrity. Working closely with our clients in North America and abroad, PipeSak continues to offer front end engineering and long-term design assistance, innovative products, in-field filling and installation services, and industry-leading customer support.front-end

quick links:high-impact

- About PipeSak ®pipeline protection

- Discover more engineered pipeline protection

- Compare PipeSaks® to traditional weights

- PipePillo®-High-performance pipeline supports

- Send us a message for a spacing and quote